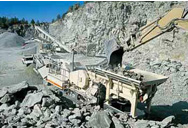

the gyratory crusher

запрос

когда мы получим ваш запрос, мы отправим по электронной почте заказные каталоги и прейскуранты в течение 24 часов.

условия поставки, условия платежа и другая необходимая информация.

the gyratory crusher

Gyratory Crusher - SpringerLink

2023年5月11日 — Gyratory crusher is a crushing equipment that uses the gyratory motion of the crushing cone in the conical cavity inside the shell to extrude, bend, and impact

Онлайн консультация

Simulation and optimization of gyratory crusher

2020年10月1日 — To study and optimize the gyratory crusher performance, taking the process of crushing iron ore by the gyratory crusher as the specific analysis object in this

Онлайн консультация

DEM simulation and optimization of crushing chamber

2024年4月1日 — The working process of the gyratory crusher is used as a specific analytical target in this paper, and the performances of the gyratory crusher, including productivity,

Онлайн консультация

Torque Analysis of a Gyratory Crusher with the

2021年8月13日 — In this paper, a DEM model was applied to a copper mining gyratory crusher to perform a comprehensive analysis of the loads in the mantle, the crushing torque, and crushing power. A novel polar

Онлайн консультация

2. GYRATORY CRUSHERS - 911 Metallurgist

2017年4月19日 — capacity: long-shaft spider-suspended gyratory crusher, fixed-shaft gy- ratory crusher, and short-shaft gearless gyratory crusher. The gyratory crusher, whether

Онлайн консультация

Industrial Solutions Gyratory crushers - ThyssenKrupp

2022年11月21日 — thyssenkrupp gyratory crushers represent today’s state-of-the-art. They are designed for high performance and, at the same time, cost-effective operation,

Онлайн консультация

Sandvik Gyratory Crushers CG800i - SRP

High reduction, great capacity. Well-designed spider bearing built from strong materials make a fulcrum point that ensures a constant eccentric throw, guaranteeing up to 90% of feed opening. Sandvik CG830i crusher

Онлайн консультация

Industrial Solutions Gyratory crushers - ThyssenKrupp

2022年11月21日 — The bevel gear and pinion of the crusher are both of a cyclo-palloid spiral type, which allows greater forces to be absorbed and greater drive power to be installed. A B C C D F E I J H K G Gyratory crusher Weights 1) Type Feed opening Mantle diameter (oversized) Speed of eccentric bushing Max. motor power Total weight of gyratory

Онлайн консультация

Types of Crushers: What You Need to Know - HUATAO GROUP

The gyratory crusher has a conical shaped head that gyrates inside a bowl-shaped outer shell, while the cone crusher has a mantle and a stationary concave ring. Additionally, gyratory crushers have a higher crushing ratio (meaning that they can crush large material into smaller pieces), a larger feed opening, and a more consistent product size ...

Онлайн консультация

Types of Crushers Explained: Everything You

2024年4月19日 — Nevertheless, gyratory crushers are usually more expensive, need more intricate foundation and have higher operating and maintenance costs as compared to jaw crushers. The decision of a jaw

Онлайн консультация

Gyratory Crusher - SpringerLink

2023年5月11日 — Gyratory crusher is a crushing equipment that uses the gyratory motion of the crushing cone in the conical cavity inside the shell to extrude, bend, and impact materials, for the purpose of coarse crushing of the materials of various hardness. It was invented in the USA in the 1870s. The equipment specification is usually represented by

Онлайн консультация

Primary Crusher vs. Secondary Crusher: Understanding Their

2023年2月28日 — The primary crusher’s function is to reduce the size of the rock or stone for easier handling and transportation. The primary crusher is usually a jaw crusher or a gyratory crusher, which operates by compressing the material between two surfaces. The jaw crusher works by moving the material between a fixed and a moving plate.

Онлайн консультация

Torque Analysis of a Gyratory Crusher with the Discrete

2021年8月13日 — Comminution by gyratory crusher is the first stage in the size reduction operation in mineral processing. In the copper industry, these machines are widely utilized, and their reliability has become a relevant aspect. To optimize the design and to improve the availability of gyratory crushers, it is necessary to calculate their power and torque

Онлайн консультация

Heavy duty, maintenance-friendly Gyratory Crusher - FLSmidth

The Gyratory Crusher “NT” incorporates all of the TC’s heavy-duty design features (Heavy Cast-Steel Shell Sections, Forged Main Shaft and Countershaft, Robust Gearing, Generous Lubrication, Long-Life Bronze Components) and focuses on coupling these historical characteristics with updated maintenance-friendly features.

Онлайн консультация

Gyratory Crusher Pro - FLSmidth

Our Gyratory Crusher Pro offers our customers high-performance crushing operations under toughest conditions from -40°C to 50°C - whether it is the heat of the Australian summer or the cold of the Norwegian winter.. Built for ultimate performance and easy maintenance, this hard rock crusher excels at the crushing of medium hard to hard rock and ore in semi

Онлайн консультация

Superior™ MKIII 54-75 primary gyratory crusher - Metso

During the development of the Superior™ MKIII 54-75 primary gyratory crusher, there have been tests conducted extensively at different mining sites in the field. The new features and upgrades have proven to be very useful, improving the profitability of primary crushing.

Онлайн консультация

What Are the Differences Between The 7 Types

2024年7月15日 — For gyratory crusher, the outer circle represents the stationary bowl covered by the concave and the inner circle represents the main shaft covered by the mantle. The main shaft rests in the eccentric

Онлайн консультация

Mathematical Modeling and Multi-Criteria

2023年5月17日 — A differential equation was derived. As a result of its solution, the rational shape of the working chamber cheek of the single-roll gyratory crusher was established, representing a logarithmic spiral arc.

Онлайн консультация

FULLER GYRATORY CRUSHER

2024年6月1日 — FULLER® HD gyratory crusher applications G5477HD G6089HD G60113HD GYRATORY CRUSHER Capacities are based on the following assumed feed distributions: Maximum feed to the crusher (F100) equals 80% of the feed opening size and 80% of the gradation (F80) is equal to or less than 50% of the feed top size and (F30) is

Онлайн консультация

Gyratory Crusher - Fote Machinery

6 天之前 — A gyratory crusher is a type of large primary crushing equipment used in the mining, aggregates, and construction industries. Its processing capacity is as high as 14,082 t/h, and the feed particle size can reach 1,350 mm. It handles medium to high hardness and aggressive materials. Therefore, it is ideal for dry to slightly wet materials, but ...

Онлайн консультация

Simulation and optimization of gyratory crusher

DOI: 10.1016/j.powtec.2020.07.034 Corpus ID: 224851552; Simulation and optimization of gyratory crusher performance based on the discrete element method @article{Chen2020SimulationAO, title={Simulation and optimization of gyratory crusher performance based on the discrete element method}, author={Zeren Chen and Guoqiang

Онлайн консультация

Application of Multibody Dynamics and Bonded-Particle

2024年7月29日 — The gyratory crusher is one of the most important mineral processing assets in the comminution circuit, and its production performance directly impacts the circuit throughput. Due to its higher energy utilisation rate for rock breakage than semi-autogenous (SAG/AG) milling, it is a common practice in operations to promote and optimise primary

Онлайн консультация

Sandvik CG810 Primary Gyratory Crusher For Maximum

Sandvik CG810i crusher is built to be robust, reliable and efficient. Connected to SAM by Sandvik, they revolutionize availability and optimize uptime by giving you actionable insights into how the crusher is performing. ... Sandvik CG800i Gyratory crusher brochure Capacity (by hour) 1,300 - 2,700 mtph (1,430 - 2,970 stph) Feed opening 1,067.0 ...

Онлайн консультация

2. GYRATORY CRUSHERS - 911 Metallurgist

2017年4月19日 — The original patent for the gyratory crusher was granted to Phile- tus W. Gates in 1881. This fint crusher was used by the Buffalo Cement Co. At the time these early gyratory crushers were developed all mining and quarrying, either underground or open pit, was done by hand; tonnages generally were small and product specifications ...

Онлайн консультация

Crushers Sizers manufactor - thyssenkrupp

The working principle of a Cone Crusher is similar to that of a Gyratory Crusher, however, it is usually in use for secondary and tertiary crushing of granite, basalt, gneiss and other hard rock, as well as in the mining and cement industries. Such as a Jaw Crusher it works on the basis of compression and squeezes the material until it breaks ...

Онлайн консультация

Primary and Secondary Crushing: Understanding the Basics

2023年2月28日 — The secondary crusher has a size reduction ratio ranging from 3:1 to 5:1. The secondary crusher can be a cone crusher, impact crusher, or gyratory crusher, depending on the hardness, abrasiveness, and size of the materials. The cone crusher is the most common type of secondary crusher used in mining and quarrying operations.

Онлайн консультация

- Золото Стиральная оборудование Малый

- цены китайской дробилки кмд кмд для песка

- мобильно дробильный комплекс inst

- щековая дробилка понравился

- 2 х вальцовая мельница цена

- вакуумная роторная сушилка с изме

- известняк конусная дробилка экспортером в малайзии

- мельница вальцевая мельница для клинкера Видео

- универсальные кормые дробилки по

- аренду рок дробилка Канада

- мельница темиртау

- машины дробилки Гана Африка

- трехмерном молотковая дробилка

- молотковая мельница новая зеландия

- небольшой каменьдробилка для продажи в австралии

- Затраты Камень дробильная установка

- harga Шанхай каменная дробилка х

- дробилка для измельчения веток св

- дробления угля Мельница электростанции Индии

- Кыргызстан каменная дробилка завод